Category

Precision Planetary Reducer 1500W Motor 110 Single Stage

PLANETX planetary reduce Planetary reducer square flange: Planetary reducer is widely used in industrial products due to

Basic Info

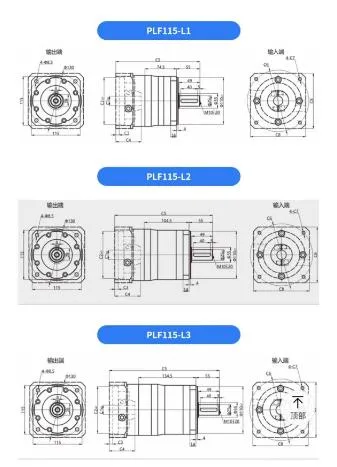

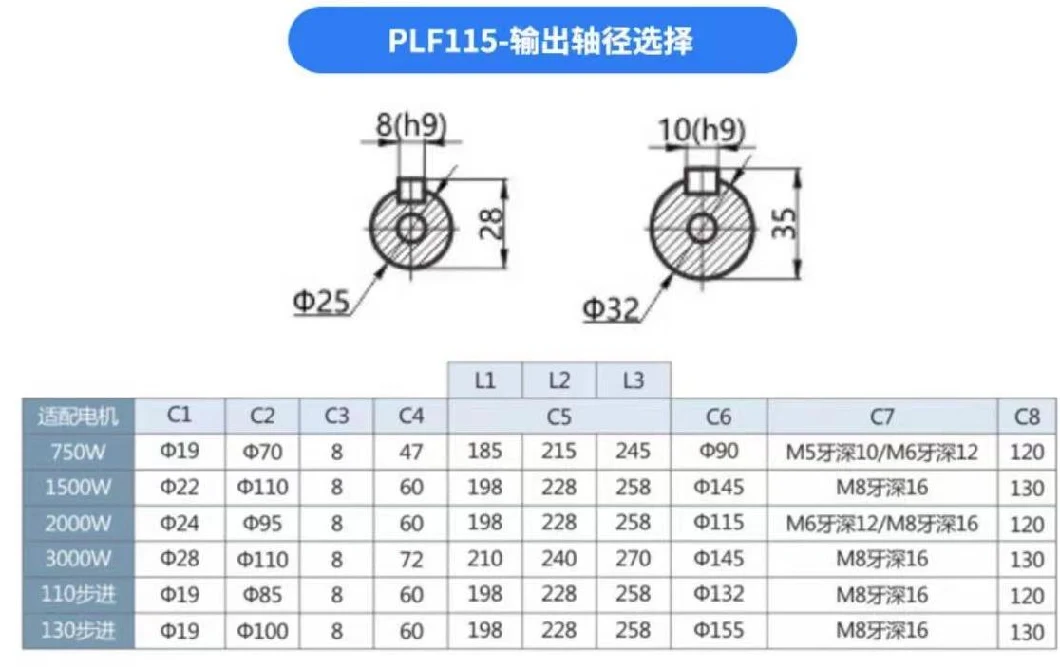

| Model NO. | PLF115-L1 |

| HS Code | 8483402000 |

Product Description

Planetary reducer square flange:

Planetary reducer is widely used in industrial products due to its small size, light weight, large torque, wide speed ratio range, high rigidity, high precision, high transmission efficiency, maintenance free and other characteristics.

The planetary reducer structure is composed of a sun gear and a planet gear to form an external mesh, and a planet gear and an internal gear ring to form an internal mesh, so that the planet gear can realize revolution while realizing self rotation and maximum transmission of guarantee force; The minimum speed ratio of single-stage reduction is 3, and the maximum speed ratio is generally not more than 10. Common reduction ratios are 3, 4, 5, 6, 7, 8, and 10. The number of reducer stages is generally not more than 3, and the speed ratio is not more than 1000; The customized reducer with partial reduction ratio can achieve 4-5 levels of reduction, and the reduction ratio can reach 100000.

Most planetary reducers are used with servo motors to reduce speed, increase torque, increase inertia, and ensure return accuracy (the higher the return accuracy, the higher the price). The maximum rated input speed of planetary reducers can reach 12000 rpm (depending on the size of the reducer itself, the larger the reducer, the smaller the rated input speed), and the operating temperature is generally between - 40 ºC and 120 ºC.

Equipped with 1500W motor

If other motors are used, please contact the customer service for drawing, welcome to consult

| Model | Unit | PLF060A PLE060A | PLF090A PLE090A | PLF115A PLE115A | PLF140A PLF160A PLF160A | Ratios(i) | |

| Stages | |||||||

Rated output torque | Nm | 16.5 | 63 | 155 | 310 | 3 | 1-stages |

| 26 | 90 | 230 | 460 | 4 | |||

| 28 | 100 | 245 | 500 | 5 | |||

| 20 | 68 | 165 | 340 | 7 | |||

| 12.5 | 43 | 95 | 195 | 10 | |||

| 19.5 | 75 | 185 | 370 | 9 | 2-stages | ||

| 31.5 | 110 | 275 | 550 | 12 | |||

| 31.5 | 110 | 275 | 550 | 16 | |||

| 31.5 | 110 | 275 | 550 | 20 | |||

| 33.5 | 120 | 290 | 600 | 25 | |||

| 31.5 | 110 | 275 | 550 | 28 | |||

| 33.5 | 120 | 290 | 600 | 35 | |||

| 31.5 | 110 | 275 | 550 | 40 | |||

| 33.5 | 120 | 290 | 600 | 50 | |||

| 24 | 81 | 195 | 400 | 70 | |||

| 37.5 | 130 | 335 | 665 | 80 | 3-stages | ||

| 37.5 | 130 | 335 | 665 | 100 | |||

| 40 | 145 | 355 | 720 | 125 | |||

| 37.5 | 130 | 335 | 665 | 140 | |||

| 40 | 145 | 355 | 720 | 175 | |||

| 37.5 | 130 | 335 | 665 | 200 | |||

| 40 | 145 | 355 | 720 | 250 | |||

| 37.5 | 130 | 335 | 665 | 280 | |||

| 40 | 145 | 355 | 720 | 350 | |||

| 37.5 | 130 | 335 | 665 | 400 | |||

| 40 | 145 | 355 | 720 | 500 | |||

| 28 | 95 | 230 | 480 | 700 | |||

| 18.8 | 62 | 135 | 280 | 1000 | |||

Max.output torque | Nm | 2/2*Nominal torqute | |||||

| Backlash | arcmin | <4 | <4 | <4 | <4 | P1 | 1-stages |

| <8 | <8 | <8 | <8 | P2 | |||

| <8 | <8 | <8 | <8 | P1 | 2-stages | ||

| <12 | <12 | <12 | <12 | P2 | |||

| <10 | <10 | <10 | <10 | P1 | 3-stages | ||

| <14 | <14 | <14 | <14 | P2 | |||

| NO-load torque | NM | 0.18 | 0.6 | 1.1 | 2.5 | 1-stages | |

| 0.17 | 0.55 | 1 | 2.2 | 2-stegas | |||

| 0.16 | 0.5 | 0.9 | 2 | 3-stegas |

Q: How to get a quick quote

A: Please provide the following information when contacting us

- Motor brand

- Motor model

- Motor dimension drawing

- What is the gear ratio

A: We all install it now, but it takes 3-5 days if it is not non-standard. Non standard 10-15 days, depending on the specific situation

Q:Do you provide samples, free or extra

A: A: You can reserve one first, and purchase it on demand